In the field of industrial power transmission, lifespan, dependability, and efficiency are important variables that impact the overall performance of the equipment. Applications for chains and belts are numerous and include heavy-duty motors, conveyors, packaging equipment, industrial lines, and agricultural gear. But maintaining the right tension in these drive systems is a persistent problem for engineers and operators. Chain slippage, vibration, excessive wear, and expensive downtime are unavoidable in the absence of brewer chain tensioners.

Since 1944, Brewer Machine & Gear Company, also referred to as Brewer Tensioner, has built a solid name here. Brewer has created a complete line of Universal Drive Tensioners, Positioners, and Idlers that remove uncertainty and increase the lifespan of belts and chains thanks to more than 70 years of innovation. With more than 1,600 partners in the US and Canada, Brewer’s chain tensioners are now utilized throughout North America and beyond.

Everything you need to know about Brewer Chain Tensioners will be covered in this extensive reference, including their background, product varieties, advantages, uses, and the reasons they continue to be the industry standard for drive system performance.

The Legacy of Brewer Machine & Gear Company

Founded in St. Louis, Missouri, in 1944, Brewer began as a small machine shop focused on custom gears and sprockets. Over time, the company expanded into three core business areas:

- Manufacturer of the Universal Drive Tensioner line – offering a variety of tensioners, idlers, and positioners.

- Custom gear and sprocket manufacturing – specializing in made-to-order components tailored to specific industries.

- Distributor of power transmission products – including bearings, motors, drives, and other critical components.

In 1959, it was only a little catalog with a few pages of tensioning solutions. Today, it is a comprehensive online database with more than 200 catalog items. Brewer’s commitment to precision engineering and problem-solving for sectors that depend on high-performance drive systems is seen in its ongoing evolution.

What Are Chain Tensioners and Why Are They Important?

A chain tensioner is a tool used in belt drive or roller chain systems to keep the tension constant. While belts stretch and loosen while in use, chains naturally lengthen with time due to wear. In the absence of appropriate tensioning, this slack results in:

- Chain vibration and whipping

- Belt slippage

- Excessive noise

- Premature wear on sprockets and pulleys

- Reduced energy efficiency

- Increased downtime and maintenance costs

Brewer’s Universal Drive Tensioners use controlled 360° tensioning to overcome these difficulties. This innovative method prolongs the life of the drive and the driven components, maintains horsepower, and guarantees quiet and seamless operation.

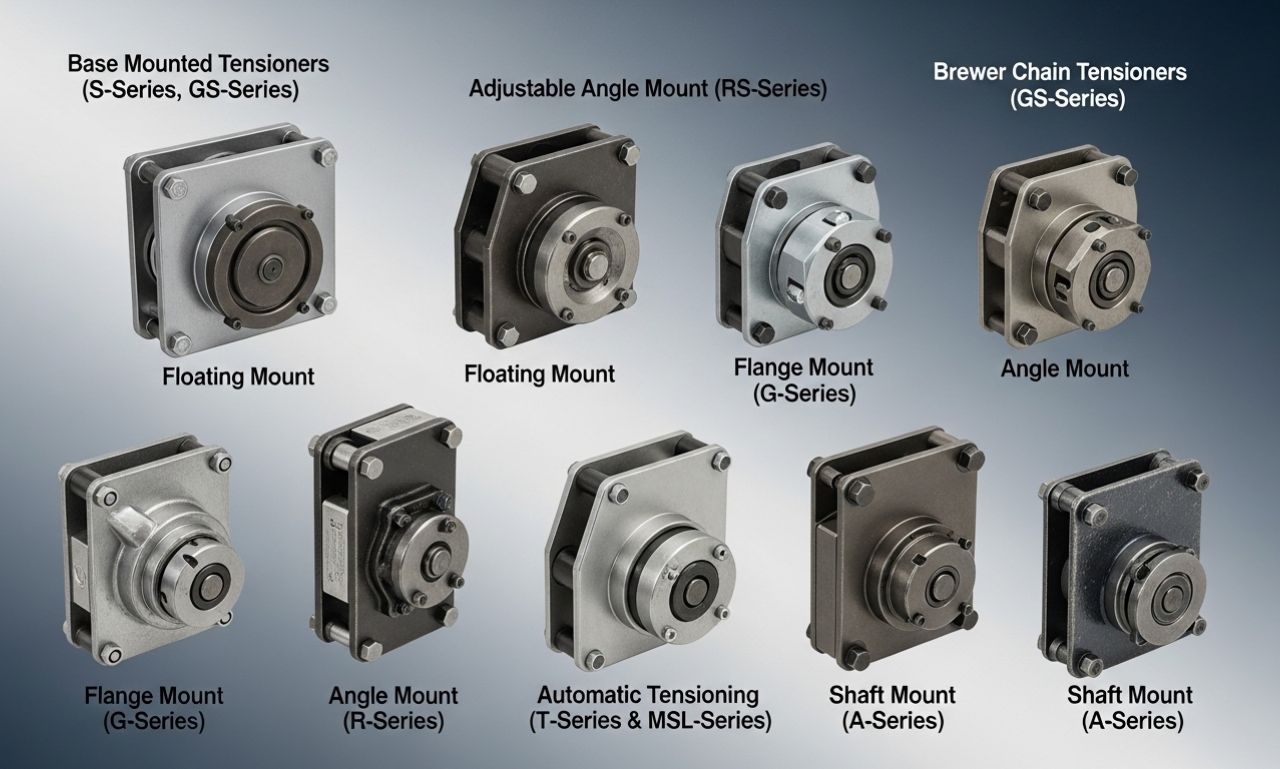

Types of Brewer Chain Tensioners

One of Brewer’s strengths lies in the sheer variety of tensioners offered. Each series is engineered for specific mounting requirements and application conditions. Let’s look at the most notable options:

1. Base Mounted Tensioners (S-Series, GS-Series)

These are among the most versatile models, providing strong support from a stationary base. Their serrated pads and rigid construction ensure accurate alignment even in demanding environments.

2. Adjustable Angle Mount (RS-Series)

Perfect for systems that require variable positioning, this design allows easy adjustment at different angles, making it adaptable across multiple applications.

3. Floating Mount (X-Series)

The X-Series tensioners excel when vibration isolation is necessary. Their floating design absorbs shock, protecting both the drive system and surrounding components.

4. Flange Mount (G-Series)

Compact and efficient, flange-mounted units are ideal when space is limited but reliable tensioning is essential.

5. Angle Mount (R-Series)

These provide an angled approach to tensioning, giving engineers additional flexibility in system layout and mounting.

6. Automatic Tensioning (T-Series & MSL-Series)

For operations that demand minimal manual intervention, automatic spring-loaded tensioners apply continuous, self-adjusting pressure. This ensures consistent performance even as chains elongate or belts stretch.

7. Shaft Mount (A-Series)

Designed to mount directly onto shafts, this series reduces installation complexity and is popular in conveyor and heavy-duty systems.

8. Screw Adjustment (H-Series)

H-Series tensioners allow precise manual adjustments using a screw mechanism, offering engineers maximum control over chain tension.

9. Slide Adjustment (L-Series)

These units use a sliding mechanism to reposition the idler easily, making them both versatile and durable.

10. Heavy Duty (BB1-4 Series)

For large-scale industrial applications with significant loads, the heavy-duty series provides robust tensioning built to handle extreme conditions.

11. Adjustable Tensioners (MHL & MVL Series)

These models combine flexibility with ruggedness, making them suitable for varied system requirements.

Key Features of Brewer Universal Drive Tensioners

Brewer’s engineering excellence is reflected in the features integrated into every product:

- 360° Rotating Arms – ensure equalized positioning and balance.

- Serrated Pads – provide firm, slip-free locking.

- Ground & Threaded Shafts – hardened shafts improve strength and wear resistance.

- Automatic Spring Mechanisms – reduce manual maintenance.

- Compact Mounting Options – allow installation in tight industrial spaces.

- CAD File Access – engineers can download DWG, DXF, STEP, and IGS files for easy design integration.

Benefits of Using Brewer Chain Tensioners

Companies that incorporate Brewer chain tensioners into their systems gain multiple advantages:

- Extended Chain and Belt Life – Proper tensioning reduces wear and elongation.

- Energy Efficiency – Eliminates horsepower loss from slippage.

- Reduced Downtime – Less frequent repairs and chain replacements.

- Quieter Operation – Minimizes vibration and noise in production lines.

- Universal Compatibility – Brewer’s catalog includes tensioners for almost every mounting requirement.

- Improved Safety – Reduces the risk of chain breakage and system failure.

- Lower Maintenance Costs – Automatic models cut down on labor-intensive adjustments.

Industries That Rely on Brewer Chain Tensioners

Brewer’s products are not limited to one sector. They are widely used across:

- Food & Beverage Processing – conveyors and packaging lines.

- Agriculture – combines, harvesters, and tractors.

- Automotive Manufacturing – assembly lines requiring precise chain operation.

- Material Handling – conveyor belts in warehouses and distribution centers.

- Mining & Heavy Industry – equipment exposed to extreme loads and harsh conditions.

- OEM Applications – Brewer supplies tensioners and idlers for original equipment manufacturers needing custom solutions.

Brewer Chain Tensioners Additional Offerings

Beyond chain tensioners, Brewer also manufactures and distributes:

- Idler Sprockets

- Flat Belt and V-Belt Idler Pulleys (cast iron & composite nylon)

- Timing and HTD Idler Pulleys

- Bushings (QD and tapered)

- Mounting Adapters

- Idler Shafts & Studs

- Hardened Linear Shafting

- Bearings

- Gearbox Repair Services

- Custom-made gears and sprockets

This extensive catalog makes Brewer a one-stop solution for power transmission needs.

Technical Resources for Engineers

A comprehensive download center featuring CAD files in DWG, DXF, STEP, and IGS formats is offered by Brewer Machine & Gear. With the use of this resource, engineers may more easily integrate Brewer tensioners into their design systems without having to rely on hunches about fit or measurements.

The whole Universal Drive Tensioner Catalog, which includes comprehensive specifications for each model in the product line, can also be downloaded.

Why Choose Brewer Chain Tensioners Over Competitors?

Several factors make Brewer the preferred choice for chain tensioning solutions:

- Proven Legacy – over 80 years of expertise in gear and drive technology.

- Massive Distribution Network – more than 1,600 distributors across North America.

- Customization – ability to produce made-to-order sprockets and gears.

- Technical Support – CAD files, catalogs, and knowledgeable staff.

- Comprehensive Solutions – not just tensioners, but a full range of power transmission products.

Final Thoughts about Brewer Chain Tensioners

Maintaining the right tension is essential in any chain or belt-driven system; it is not an option. The most dependable, adaptable, and durable answer to this crucial need is offered by brewer chain tensioners. Brewer’s product line includes almost every industrial situation, from base-mounted models to automatic self-adjusting systems.

Brewer Machine & Gear Company continues to be the industry leader in tensioning solutions thanks to its decades of experience, CAD support, nationwide distribution, and robust engineering.

Brewer Chain Tensioners provide the performance and dependability that contemporary industries want, whether you are an OEM searching for scalable solutions, a maintenance engineer trying to minimize downtime, or a distributor hoping to serve a variety of sectors.